Lean Six Sigma Retail Consulting

What is Lean Six Sigma?

The term ‘Lean Six Sigma’ is a combination of two concepts – Lean and Six Sigma. Herein, we will refer to it as LSS. The thread that binds them together is process improvisation. The focus of Six Sigma is to reduce the deficiencies and variations in the business processes for achieving the best output in the best possible way. The objective is to chalk out process redundancies and defects. Driving out ‘what is not necessary’ is associated with the concept of ‘Lean’. With both the concepts combined, we get processes that are fit – just and exactly as they need to be – while retaining their objectivity. For instance, no matter what kind of grievance a customer comes up with, the complaint resolution process in place should be able to address it in the best possible way. If it is within the defined framework, it helps save resources by eliminating ‘what need not be done’ and defining ‘what needs to be done’. If a customer comes up with a complaint that is not mapped within the process, the customer support team will not know what to do and what not. It is something common to see even in big retail stores. More than a concept, LSS is an approach and a way of thinking to enhance the process and operational capabilities.

Lean Six Sigma in Retail Industry

The concept of Lean Six Sigma finds its roots in Japan and the USA. Because of its universal utility, numerous industries have embraced LSS since its inception. This includes the retail industry as well. When processes get involved, process improvisation becomes a necessity. And when process improvisation is sought, LSS is a powerful solution. Today, retailing is a complex value chain. There is hardly any profitable way left to do it mediocre. It is fast, technology-driven, and needs the agility to constantly align itself with the external environment. For instance, if a competitor drops prices, a suitable response must find its way. If the response is a reciprocated one, it would call for changes in the software systems and the packaging function. What does a process have to do here? The answer is – nearly everything. The relevant processes must have room to incorporate such changes in a predefined format. If the processes are not designed accordingly, making sudden changes to them could be chaotic and resourcefully expensive.

Lean Six Sigma for retail businesses

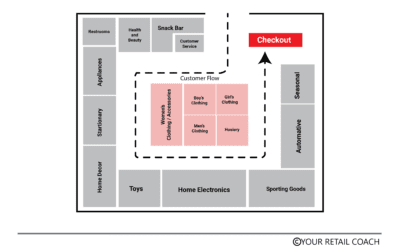

Optimal space utilisation

With space as a constraint for most small and medium-scale retail businesses, retailers often struggle to merchandise at the full demand potential. Somewhere customer experience and maximising stocking capabilities are traded for one another. Can LSS help here? Retailers should know the maximum floor and shelf space available at any time. Then they need to realign their SKU merchandising strategy with this constraint. Multiple processes or operations like demand forecasting, merchandising planning, purchasing, staffing, logistical planning, etc. get involved here. The space constraint affects how these processes are designed and executed. Optimal space utilisation may seem like a routine business goal, but the thinking required for the workaround emanates from LSS.

Inventory optimisation

The three big objectives of inventory management are timely availability of stock, no over or under-stocking, and preventing undue investment into inventory. Timely availability of stock requires that reorders are placed on time. Avoiding under or overstocking calls for the determination of the right ROQs (Re-Order Quantities). To prevent any unnecessary investment into inventory, retail businesses need to ensure that demand and sales forecasts are highly accurate if not exactly. These decisions are all part of various processes. The application of the Lean Six Sigma philosophy seeks to achieve accuracy in making these decisions and planning for the same.

Logistics optimisation

Whether logistical facilities are internal or hired, there are costs attached. If it is a case of hired services, the goal should be to limit the number of orders per supplier within a cycle. If logistics is an in-house department, the goal should be to optimise the usage of logistical resources. Since logistics are primarily driven by purchase and reorder requirements, the process is co-dependent. Applying Lean Six Sigma necessitates that the use of logistical services or resources is optimised to prevent unplanned and low-value trips. We can use the instance of a water jar delivery business. To-and-fro trips cost more than a linear up-and-down trip. With Lean Six Sigma in focus, the movement has to be planned and orders received in advance.

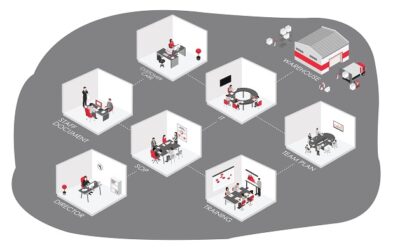

Team Management

Unlike in production, gauging staffing requirements in the service industry is a tricky area of work. Should you have four sales staff or five? Additional staffing means an additional burden on the salary budget. It costs heavily for small and medium-sized retail businesses. This is where planning and processes come into the picture. From manpower assessment to exit formalities, having lean and high-quality processes ensure that all HR activities take place in sync with the organisational and functional prerogatives. If three suitable candidates made it for two vacant positions, you need not feel tempted to hire all three of them in anticipation of finding a role for the extra hire that already does not exist in the organisation structure. Decide in advance what should be in the process and then do not deviate from the process.

Focused marketing

Retail businesses can no longer shy away from digital marketing. At the same time, they also cannot ignore the ROI of their digital marketing efforts. That makes digital marketing an area of work requiring perpetual fine-tuning. But this fine-tuning of planning and strategies requires better insights. And after we have a better plan and strategy, we are better equipped to improvise the processes to execute them. LSS approach leads to the consideration of implementing advanced analytical solutions for effective and efficient digital marketing management.

Customer Experience

The efficiency of outbound processes and operations carry a major impact on customer experience. The goal is to make the shopping journey convenient for customers at any touchpoint or transaction. Take the example of a retail grocery store offering on-call ordering facility. Customers should be able to easily access the contact numbers provided to place the orders. There should be a sufficient number of lines available. The call waiting should be activated so that callbacks can be made. This order receiving process must be designed keeping in mind the constraints and customer experience. When the process planning is meticulous, the chances of missing out on orders or disappointing customers are reduced to a great extent. Furthermore, the management should be able to track the call list. The application of the Lean Six Sigma philosophy lends a strong intent to eliminate errors and make processes more accurate.

Customer Loyalty

Customer loyalty is built over years. It comes with long-held consistency and improvisations in the quality of the products and services and customer experience. And achieving this consistency requires strong processes and perpetual process improvisations. LSS philosophy provides the required vision and tools to maintain processes in their superlative forms. For example, if a supermarket store is consistently able to stock a wide variety of packaged frozen foods, in the long run, it partly becomes a part of its brand perception and aids in building customer loyalty.

Becoming growth-ready

The existing operational system plays a critical role in the growth and expansion projects of a retail business. The tested and proven processes, with or without improvisations, can be replicated with more confidence. But if the current working systems are not well-defined and streamlined, replicating them would mean replicating the same operational problems in the new branches. Robust processes validate themselves for successful replication for growth and expansion purposes.

Who we are & how we can help

We are a boutique retail and eCommerce business consultancy brand. With more than ten years of experience in delivering unique and diversified business solutions, we have worked with over 500 clients in 20+ industries. Process management and SOP solutions have been our undisputed ‘sphere of expertise’. We deploy expert process consultants in service design and delivery. For more information on our Lean Six Sigma retail consulting services, please visit our website to speak to an expert.

Get Advice for Six Sigma Retail Consulting

Related Blogs

Retail Store Layout Strategy: What to Consider and How to Plan

Why Store Layout Matters in Retail The layout of a retail store carries several internal and external business implications. Layout is an important physical aspect of branding efforts. It creates an opportunity to create the desired atmosphere in stores thereby...

Reliance Gourmet Supermarket – “Freshpik” Case Study

The fifth-largest and preferred retail destination globally, the Indian retail industry is one of the fastest-growing segments in the world. India is experiencing unprecedented growth with retail development taking place not just in major cities and metros, but also...

How to Organize & Grow Supermarket / Hypermarket

Already running a supermarket store and wondering how to scale it further? Are you contemplating what should be your next steps to accomplish your vision to organize and manage multiple stores? If this is what you are looking for, then you are in the right place. Your...

We work only for Visionaries.