The Signavio supply chain modeling enhances agility by providing an individually customized, data-enhanced view of the supply process. With that skillset, companies can simulate, optimize and respond to the latest disruption, while still getting the goods moving, planning better and enhancing operational risk.

Modern companies are facing unpredictable changes in demand and logistics. Signavio allows companies to understand dependencies, play with “what-if” scenarios and align operations to strategic goals. The ultimate outcome is an accelerated and intelligent decision-making capacity that is based on impacted and collaborative processes.

Why Supply Chain Agility Matters for Modern Businesses

Agility in the supply chain involves more than speed; it is about flexibility, foresight, and responsive operations. Companies that are quick to adapt can manage disruptions and limit operational impact and damage, while others lose precious time, money, and consumer confidence.

Signavio supply chain modeling facilitates agility, as it provides a clear understanding of every operation, from procurement to delivery, at a process level, and how every function interacts with each other. Through modeling the real-world realities of every organization’s supply chain, companies can understand the potential impacts of a supplier shortage or significant demand increases before they happen.

A supply chain that is designed well provides the following:

- Visibility: real-time view of processes and dependencies.

- Agility: quick redesign of logistics routes or product source plans.

- Continuous-improvement: measurable insight to create change.

- Alignment: operate to strategy.

Agility is not just a competitive advantage; it is a way to survive. It is about finding the ability or opportunities to improve your organization’s supply chain. Signavio provides your organization the insights to develop enhanced process transparency and analytics across the organization, to continuously evolve your supply chain and convert change into opportunity.

How Signavio Supply Chain Modeling Builds Flexibility and Insight

What makes Signavio supply chain modeling so valuable is its unmatched ability to visualize and optimize complicated process networks. It maps every touchpoint (suppliers, warehouses, logistics partners, customers, and so on) to show where there are delays and where there are improvements to be made.

With Signavio simulation, teams can model what-if scenarios prior to making changes. For example, if a shipment route is delayed, the simulation predicts what would happen downstream in the production schedule or delivery timeline. This helps to make plans smarter and saves costs when things go wrong.

What this means for organizations is:

- Operational clarity: Every process is visible and measurable.

- Testing scenarios: The manager can examine many alternative solutions quickly.

- Informed decisions: What actions to take are based on actual events, not guesses.

- Collaborative planning: Teams across functions get on the same page with shared learning.

In this way, modeling provides organizations with confidence to change direction faster without jeopardizing stability. Agility is not achieved through reactive thinking; it is achieved through foresight, which is exactly what Signavio provides.

The Power of Simulation in Supply Chain Decision-Making

Signavio simulation enhances visibility into the future. Rather than relying solely on static reports, companies can simulate multiple operational scenarios with their supply chains before taking action. Simulation enables the experimentation of supply chain strategies in a no-risk digital setting, supplying the team with information that allows them to simulate across a range of conditions related to demand surges, delays from shipping, or material shortages in the supply of goods.

By simulating workflows in whole, teams are able to visualize the impact of one decision on the rest of the value chain. They can then use these simulation indicators to improve routing, support better sourcing decisions, and recover faster from disruptions. For example, if a manufacturer wanted to change suppliers in Asia, they could simulate the impact of that change on delivery time in Europe prior to making a supplier switch.

Some of the benefits of simulation within Signavio include:

- Predicting performance under conditions of change.

- Determining the best process conditions.

- Preventing cost overruns through pre-analysis.

- Building resilience through data based knowledge.

Simulation allows organizations to realize supply chain agility from general concept into a discrete, measurable and repeatable process. Simulation is a strategy that meets science by allowing organizations to turn uncertainty into structured advantage.

Delivering Tangible Signavio Business Value

Agility has value only in the results you see from that agility. The business value of Signavio can be measured in improvements afloat with improvements to lead time, cost, and process reliability, where direct operational improvements lead to tangible and quantifiable business value.

By using process modeling, simulation, and analytics, Signavio aids companies in understanding how every change makes an impact on financial and strategic objectives. Any process designed with Signavio, once planned for execution, will yield returned value in either saved expenses or increased productivity.

Results include core business value outcomes that deliver:

- Profitability improvement – wasted work is cut and resource assets are used wisely

- Speed to market – streamlined activities result in faster delivery cycles

- Customer satisfaction – use of performance-based outcomes build trust

- Scaled agility – a process can be fast tracked across departments in scalability changes

Agility is clear to leaders to demonstrate that agility impacts transformation initiatives to stakeholders, a process improvement can now be a reliable data point that demonstrates value and the agility to support enterprises’ goals.

How LeanIX IT Portfolio Strengthens Supply Chain Agility

Every modern supply chain relies on technology now more than ever. When Signavio is integrated with the LeanIX IT portfolio, businesses can gain total clarity into their business processes and the IT systems that support them.

This connection closes the historic divide between operations and technology. Companies can now see what applications are powering their most critical supply functions, be able to see redundancies, and ensure that technology investments are made to support operational needs.

There is practical benefit in the following:

- Mapping IT dependencies to individual supply chain workflows.

- Sweeping away redundant tools that slow down business processes.

- Link transformation initiatives to IT-enabled capabilities.

- Finding that enables smarter governance and compliance.

For example, if a supply chain process is bottlenecked by an out-of-date ERP module, LeanIX can display connections and dependencies, while Signavio can model the impact of replacing that module. This partnership creates a digitally connected ecosystem where all technology and processes are omni-connected to drive agility, transparency, and efficiencies.

Enhancing User Adoption with WalkMe In-App Guidance

A system’s effectiveness is only as good as its users. WalkMe’s in-app guidance ensures that employees will adopt and use Signavio, without a lot of training. WalkMe offers interactive and step-by-step guidance for users in the context of the platform, empowering them to model and optimize processes confidently.

By guiding users in real time, WalkMe shortens the time to learn and helps users avoid making mistakes. WalkMe also reinforces best practices by helping employees remember to follow proper procedures while they are working.

WalkMe enacts the role of leading adoption in the following ways:

- Guidance in context: Tips are only revealed when they are needed.

- Error proneness: Users receive messages before making mistakes.

- Efficiency: Users complete tasks faster and with accuracy.

- Consistency: All users follow the same processes.

Through this seamless way of learning, process agility is not just something we hope for, but is a way of life in each process every day. With WalkMe and Signavio together there is a self-sustaining culture of improvement, where technology and people can maintain and be in sync.

The Measurable Benefits of Signavio Supply Chain Modeling

When the platform is used as intended, Signavio provides provable benefits across speed, cost, and collaboration. Competitors’ process intelligence and simulation capabilities help organizations prosper in times of constant disruption.

Benefits include:

- Fast adaptability: Quickly respond when supplier or logistics change.

- Operational efficiencies: Remove waste and improve workflows.

- Cost containment: Use data leverage to protect unspent money on avoidable costs.

- Process alignment: Ensure all departments are aligned to move toward shared outcomes.

- Data-informed decision-making: Move from intuition to process intelligence behind decisions.

Additionally, LeanIX IT portfolio integration and WalkMe in-app guidance create environments to support more of these outcomes – where tech can enable work and staff can do work perfectly. Essentially, Signavio translates the complications of global supply networks into clarity and control.

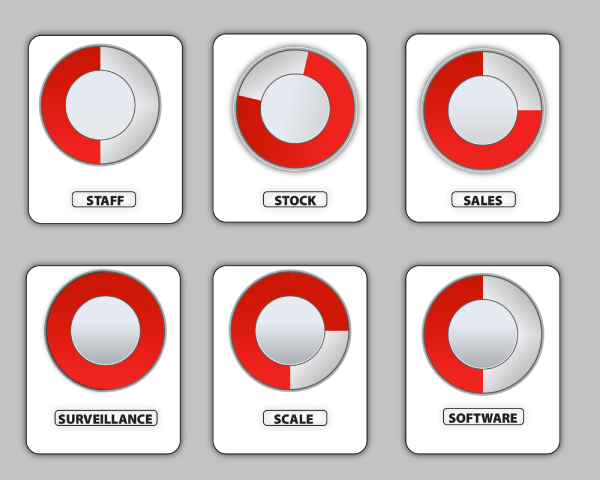

Retail Healthometer

Check the health of your business? Are you ready to organize & scale ?